Skin absorption of isocyanates: Use of MDI adhesive

The Challenge

During the manufacture of industrial flooring, chipboard panels

were coated with isocyanate-based adhesive (MDI, methyl diphenyl

diisocyanate) before metal facing plates were manually attached to

either side. The panel was then mechanically crimped prior to being

manually taken off the production line for storage. The

workers were wearing leather gloves, primarily for protection

against physical injury during the manual tasks. Urine samples

showed that body burdens for MDI substantially exceeded the UK

guidance value in a number of workers.

The Solution

HSE looked at the correlation between airborne MDI and levels

found in urine. This showed that the urine samples indicated

substantially more MDI exposure than expected from the measured air

levels.

In light of this, and the nature of the handling tasks within

the process, it was suspected that skin exposure could be

contributing to the overall body burden. The glove regime was

reviewed and it was decided to replace the leather gloves with

polyester gloves that had a polyurethane palm. These would provide

chemical protection and, being cheaper, could be changed more

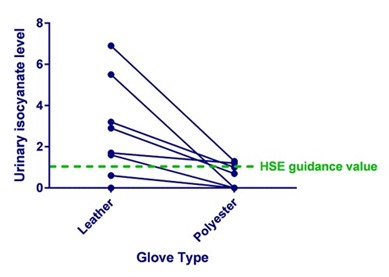

frequently. The graph below shows individual worker results for

both the leather and polyester gloves. In virtually all cases, use

of polyester gloves reduced the exposure of the worker to below the

guidance value.

The Outcome

Following the intervention, body burdens were significantly

reduced, with all workers tested showing lower levels in urine.

Whereas three-quarters of the workers exceeded the biological

monitoring guidance value before the intervention, only a quarter

still exceeded it afterwards, and then only marginally. The

airborne levels of MDI remained similar after the intervention,

indicating that dermal contact had been the primary source of

exposure, as suspected.

A straightforward improvement in the glove regime markedly

reduced worker exposure to a potent skin and respiratory

sensitiser, thus reducing the likelihood of future ill-health.

With thanks to Aspen Environmental.

Back to the top