Aerospace Testing

HSE has worked with the aerospace

sector for several decades and in that time, we have helped to make

air travel safer, faster and more efficient.

In the safety-critical environment of the aerospace industry, it

is vital that new materials, components and equipment are tested

and evaluated for performance.

That's where our testing and monitoring services can help.

Aerospace testing

As well as testing to recognised

standards, we excel in solving some of the most difficult

challenges that no one else can. The breadth of our capability and

the versatility of our testing facilities means that we can design

and deliver bespoke solutions to some of the most complex issues in

aviation.

Contact TestingEnquiries@hse.gov.uk with your testing

requirements.

Jet Zero Solutions

The Government's Ten Point Plan

positions the UK at the forefront of aviation to push forward low

carbon travel for combatting climate change.

The plan will drive the uptake of sustainable aviation fuels,

invest in R&D to develop zero-emission aircraft and develop the

infrastructure of the future at our airports.

Developing the new and innovative technologies, as well as the

infrastructure required to meet these objectives within the

timescales demanded, is going to be a challenge.

Innovating with agility and incorporating robust science and

evidence from the start to build-in safety, with the regulatory

landscape in mind, is imperative if we are to get right first-time

round.

That's where HSE can help. Read about our Jet Zero solutions here.

Contact us

Find out how we can help clients in

the aerospace sector fulfil their testing requirements by

contacting:

Nigel Moss

nigel.moss@hse.gov.uk

+44 (0)203 028 2133

|

|

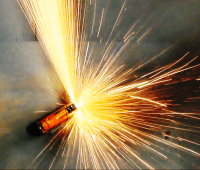

Aviation

Powerplant Fire Testing Facility

In our dedicated Burn Hall we provide aerospace clients with

independent and flexible engineering and certification tests to

ISO 2685 and AC 20-135 standards.

We offer both the propane and liquid fuel burner options included

in the standards, alongside an FAA-design 'NexGen' burner aligned

with future plans for powerplant fire testing. |

|

High Pressure Combustor Facility

Our high-pressure combustor is based on a modified

Rolls-Royce 'Tay' combustor can using either liquid or gaseous

fuels (for example Jet A1 or methane) and allows 3-minute run times

with a combustion flame in excess of 50 bar / 2000 K.

|

|

Electrostatic Fluid Flow Facility

This large-scale facility can be used for measuring

electrostatic charge generation on liquids and components

(including composites) during fluid flow.

|

|

Combined Cycle Gas Turbine Facility

Clients can use this facility to investigate the performance and

safety of combined cycle gas turbine systems (including heat

recovery systems) and operation on novel fuels.

|

|

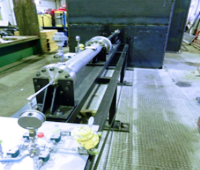

Bore Gas Gun

Our 25mm bore gas gun can test projectile masses typically

ranging from 1g to 1kg at speeds up to Mach 1, with the potential

for more depending upon requirements. The gas gun enclosure has two

ports for high speed video that can enable co-efficient of

restitution calculations. This facility can be used

for test coupons, whilst a large enclosure also allows us to test

components.

|

|

Battery Safety Facility

Used to study the risks arising from battery manufacture,

transport, storage and use, our battery safety chamber is a

purpose-built enclosure with a separate control room from which our

battery testing specialists can initiate and monitor the failure of

cell and battery packs. For full details, click here.

|

|

Multi-Purpose Engineering Laboratory (inc. Strong

Floor)

Our Engineering Laboratory houses a range of test equipment

including: 50t/150t/250t universal test machines; a Rosand impact

machine, and a strong floor.

This equipment is suitable for benchmarking materials and for

small component testing.

|

Back to the top